Turnkey Plants: What It Really Means and Why It Can Make a Difference?

Turnkey Plants: What It Means in the Soap Production Industry

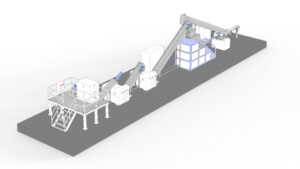

When referring to “turnkey plants” in the context of soap production, it means complete solutions that include all the necessary phases to make a soap factory operational, from initial design to commissioning. This approach involves entrusting a single point of contact capable of managing every technical and organizational detail, thereby reducing the margin for error and accelerating the time to productive startup.

Rising develops turnkey plants for soap production, designed to perfectly adapt to the specific needs of each client. Each project starts with an in-depth analysis of production requirements and translates into an integrated system, complete with machinery, automation, plant engineering, and technical support. With a single supply, you can obtain a plant that is ready for use, optimized in terms of costs, timelines, and performance. If you are planning to build or upgrade your soap factory, choosing a turnkey solution can truly make a difference.

Choosing Turnkey Soap Production Plants

Opting for turnkey plants for soap production simplifies project management, allowing you to focus on the final outcome. The entire process—from project design to startup—is overseen by a single supplier. You won’t need to coordinate multiple companies, technicians, or vendors; instead, you’ll have one responsible point of contact for every phase, ensuring a clear and cohesive vision. This approach significantly reduces startup times because all activities are integrated into a continuous, scheduled workflow.

The plant design, machinery production, installation, testing, and staff training are all coordinated in a unified plan. Consequently, unexpected issues are minimized, and time and resource waste is avoided. Another key advantage of turnkey plants is cost control: a single contract with a clear timeline and investment framework protects against unexpected expenses and delays. Additionally, optimizing the entire plant ensures maximum productivity from the first production cycle.

On Rising, you can rely on complete turnkey plant setups for soap production, specifically designed to deliver tangible results. Our tailored solutions address your needs directly, enabling you to start production quickly with machinery tailored to your requirements, already integrated and tested for reliable, high-performance operation.

From Concept to Operation: All Stages of Turnkey Plant Realization

When choosing turnkey plants, each phase is managed by a single technical supplier, ensuring seamless integration and fluid coordination across the entire process. It all starts with the design phase: engineering is developed based on your specific requirements, considering the type of soap, production volumes, and available space. Every detail is studied to create a plant perfectly aligned with your expectations.

Once the project is finalized, production machinery for soap manufacturing is built. All components are constructed to operate in synergy, ensuring reliability and continuous operational capacity. The installation phase follows a precise plan that minimizes downtime and streamlines preparation for operational startup efficiently.

Commissioning represents a critical phase, where the entire system is tested to ensure all process parameters are met. Additionally, personnel are trained directly on the new plant, with technical alignment to ensure autonomy and safety in daily operations. Rising accompanies every project until full operational readiness, providing continuous support and post-installation assistance. Entrusting a single partner for all phases reduces risks, avoids delays, and delivers a turnkey plant ready to produce soap efficiently and competitively.

Why Choose Turnkey Plants for Your Soap Production Facility?

Opting for turnkey plant solutions allows you to build a more efficient, reliable, and easy-to-manage soap production facility. When a single provider oversees every phase—from design to startup—you gain technical consistency, controlled timelines, and reduced risks. This approach minimizes errors, limits downtime, and ensures production begins on schedule, aligning with your business goals.

Integrated Systems for Seamless Operations

The synergy between machinery and systems is key. Every component in the turnkey plant is engineered to work perfectly together, ensuring a continuous, optimized production flow. This guarantees consistent soap manufacturing with precise, repeatable quality parameters—critical for maintaining brand standards and meeting market demands.

Sustainability & Cost Efficiency

Modern turnkey systems prioritize sustainability: digital energy monitoring, smart resource management, and eco-friendly technologies help reduce waste and lower operational costs. These features not only enhance profitability but also position your business as eco-conscious and forward-thinking.

End-to-End Support for Your Success

Whether designing a new facility or upgrading your line, a comprehensive turnkey package provides custom-designed facilities, training for your team, and ongoing technical support. Partnering with Rising means working with experts who simplify every step—from concept to operation—ensuring your soap factory is modern, competitive, and future-ready.

Why Choose Turnkey Solutions?

- Technical consistency: Reduced errors and downtime.

- On-time production: Predictable timelines, no delays.

- Continuous efficiency: Synergized machinery for optimal output.

- Sustainable ROI: Lower energy costs, minimized waste.

- Expert guidance: Risingsupports every phase for seamless execution.

Turnkey plants are the smart choice for businesses aiming to build a solid, competitive soap production facility that adapts to evolving industry needs.

Rising and turnkey plants: a technical partner for your success

Choosing Rising for the realization of turnkey plants means entrusting your project to a technical partner who has an in-depth understanding of every aspect of soap production. Each plant is custom-designed with the goal of offering you a complete, efficient, and ready-to-operate solution. The experience gained in various production contexts allows us to adapt each project to the specific needs of your business. Rising handles all aspects from initial engineering to machine construction, installation, training, and after-sales support. This integrated approach allows you to work with a single point of contact, reducing complexity and the margin for error.

Attention to detail and high-quality construction ensure a solid, reliable plant capable of supporting intense production cycles. The solutions developed by Rising include state-of-the-art technologies, advanced automation systems, and real-time quality control tools. Each soap production plant is designed to last and grow with your business.

Trusting Rising is a strategic choice: not just a machinery supplier, but a technical partner capable of supporting the development of your soap factory, helping you achieve efficiency, quality, and continuous production right from the first cycle. With a turnkey plant, you can build a solid foundation for a successful business.