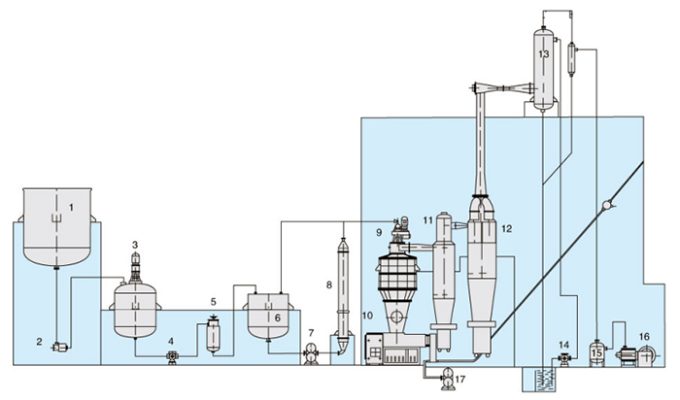

鹸化プラント

The saponification by using oil & fat smelting and water washing methods to get purity neat soap, the neat soap is liquid, and it can be solidified by the vacuum drier.

Saponification production process

- 1. Soap-radicel Cauldron

- 2. Coarse Filter

- 3. Crutcher(Concoct Cauldron)

- 4. Filter Pump

- 5. Refining Filter

- 6. Soap inlet Container

- 7. Gear Pump

- 8. Tubular Heat Exchanger

- 9. Vacuum Spray Drier

- 10. Pelletizer

- 11. 1st Cyclone Separator

- 12. 2nd Cyclone Separator

- 13. Barometric Condenser

- 14. Water Circulating Pump

- 15. Foam Eliminator

- 16. Vacuum Pump

- 17. Soap Pellet Air Blower

Featured Product

Soap Reactor

Our stainless steel reactor are designed to meet the demands of diverse industrial applications, including chemical processing and light industry. Engineered with precision and built with high-quality materials, these reactors are equipped with a variety of heating and agitation options to ensure optimal performance and product quality.

お問い合わせ

塩と石鹸の製造ソリューションに関するご質問や詳細情報が必要ですか?私たちのチームが、お客様に合わせたアドバイスと専門的なサポートでお手伝いいたします。今すぐご連絡いただき、最高品質の生産を実現するための当社のサポートについて詳細をご確認ください。

Saponification, vacuum drying process equipment