화장실 비누 마무리 라인

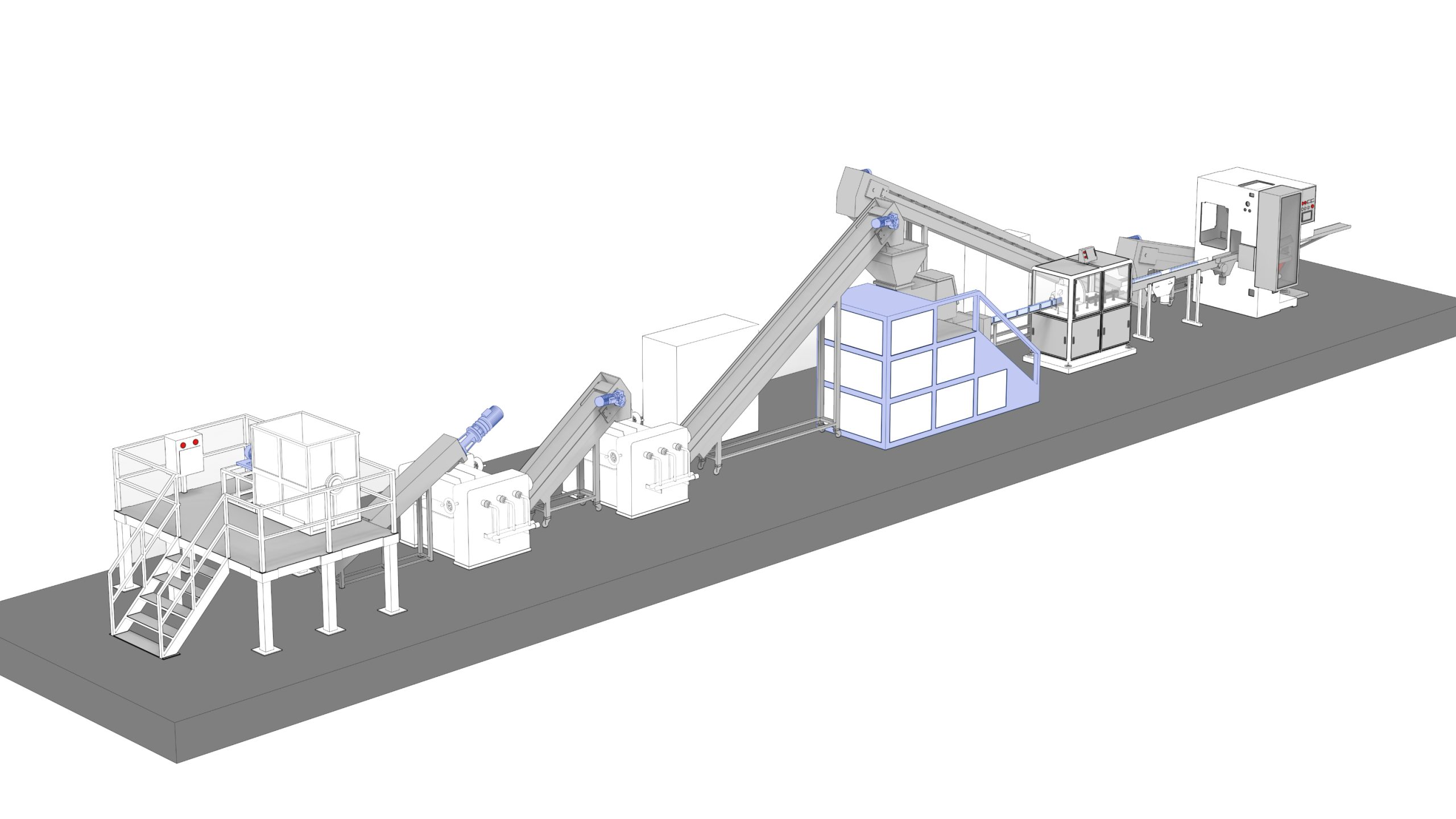

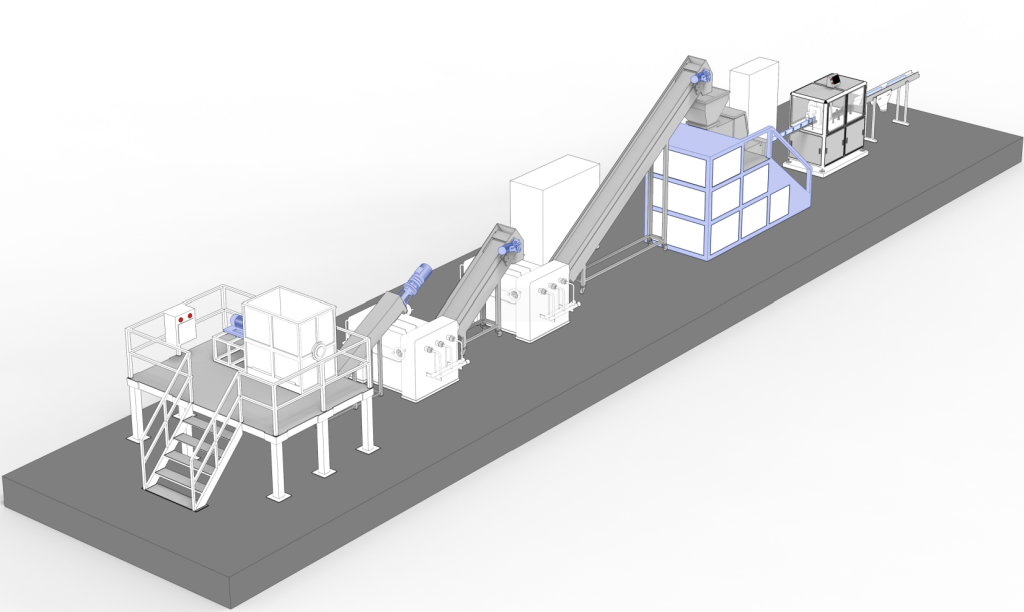

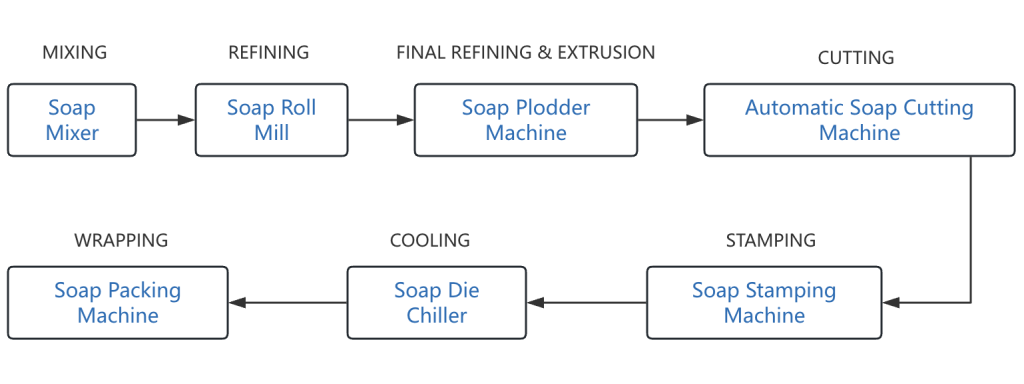

The toilet soap finishing production line begins with soap noodles and progresses through a mixer, milling equipment, and vacuum plodder, followed by cutting, stamping, and other finishing processes. The final soap product is smooth, dense, resistant to cracking, and features a bright appearance.

화장실 비누 마무리 라인

The capacity of 500-2000kg/h is the normal range of soap production lines required in many soap manufacturing countries. We can provide any range of this according to the client’s requirements. We provide the service of sending technicians for guidance on installation, commissioning, and training.

세탁 비누를 위한 종합 솔루션

당사의 비누 생산 라인은 고객의 다양한 요구를 염두에 두고 설계되었습니다. 소규모 장인 작업장이든 대규모 산업화 생산이든 상관없이 맞춤형 솔루션을 제공할 수 있습니다. 장비의 구성과 수를 조정하여 500kg/h에서 2000kg/h까지 다양한 생산 능력을 쉽게 실현할 수 있으므로 생산 효율이 시장 수요에 밀접하게 부합합니다.

Soap Mixer : One mixing shaft with two mixing paddles, is driven by the motor through the gear box and rotating continuously to mix soap noodles, flakes are mixed with all kinds of liquid and solid ingredients inside the mixer chamber. After the mixing, products are discharged through air cylinder controlled discharging door.

Soap Roll : Mill The Three Roll Mill is used for soap refining in soap making machine. Three rolls are horizontally placed with different rotating speeds. The refining function is achieved by pressing and squeezing force between the adjacent rolls.

Soap Plodder Machine : The duplex vacuum plodder is very important in the soap making machines.This machine has two stages, driven by independent transmission system. The first plodder is acting as a simplex refining to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out in billets through the orifice to feed the downstream cutter or stamper.

Automatic Soap Cutting Machine : 스테인리스 스틸 나이프 블레이드, MITSUBISHI 주파수 변환기, 서보 모터, 서보 컨트롤러, OMRON PLC 및 로터리 코더, 독일 Siegling 컨베이어, 7인치 컬러 터치 스크린을 적용합니다.

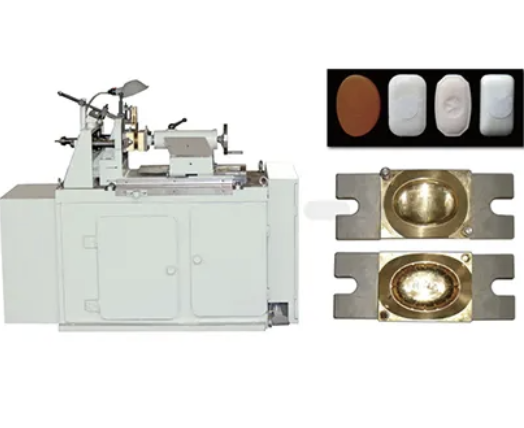

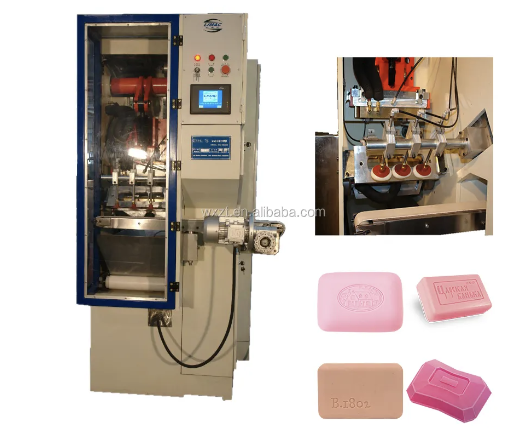

Soap Stamping Machine : In the stamping process, each soap bar is embossed or molded with the brand logo or design using a automatic soap stamping machine, giving the product a finished and professional appearance.

Soap Die Chiller : The soap die chiller is to chill the soap die (mould) in the soap making machine line. It can refrigerate the cooling liquid rapidly, and transport the cooling liquids to the heat exchanger by the pump.

Soap Packing Machine : This machine is used to package finished soaps at the end of production. It can create various types of packaging using a range of materials.

Soap Production lines with different capacities

Lab Soap Machine/ Pilot Soap Machine (make soap no more than 100g)

100kg/h or 150kg/h Soap Machine

문의하기

비누 생산 솔루션에 대해 궁금한 점이 있거나 자세한 정보가 필요하신가요? 저희 팀이 맞춤형 조언과 전문가 지원으로 도와드리겠습니다. 지금 바로 문의하여 최고 품질의 제품을 생산할 수 있도록 도와드리는 방법에 대해 자세히 알아보세요.

What’s your story? We’ll help you tell it.

Team Support

자주 묻는 질문

Networking