Product Application

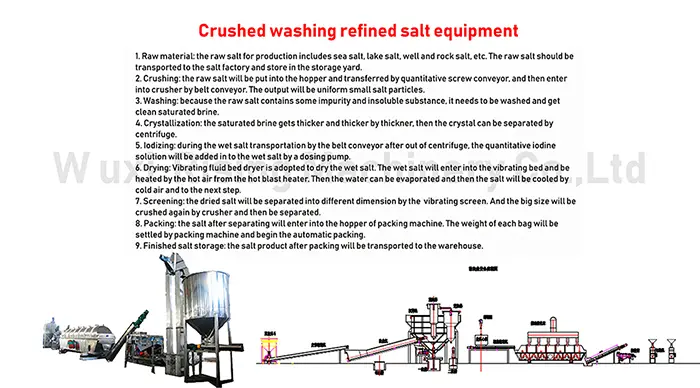

The crude salt is transported to the screw salt washing machine for the first washing, then crushed by roller crusher to get the salt with suitable size. This kind of salt will be washed by stirring washing machine and countercurrent washing machine for two or three times, and then get purified salt. The next step is to enter the centrifuge to remove most of the water. After this the salt will be dried by vibrating fluid drying bed for the drying to get the finished salt with 0.4% water content. During the salt transportation from centrifuge to vibrating fluid drying bed, there will be an iodized machine to add iodine into the salt. The final step is to packing the finished salt.

High quality salt production line

Customized Salt processing line machinery

The four washing is as follows:

1, First Screw washing

2, Second screw washing

3, Stand-up stirring washing

4,Countercurrent washing

Three-crushing is as follows:

1, First crushing

2,Wet crushing

3,Dry crushing

The combination of wet crushing, dry crushing and different ways of washing has greatly improved the salt quality.

The above operation is subject to adaptation according to the users’ different requirements due to the use of crude salt of different quality

Main Features

Crushed washing refined salt equipment line include: stainless steel elevator, mixer, conveyor, crusher, salt washing machine, iodize machine, centrifuge and drying machine, dust remover, packing machine and etc.

For the capacity of the production line, we can produce based on customers’ requirement. The capacity is 500kg-15ton/hour.

Advantage of our equipment line:

1) The high quality refined salt product has high purity, shiny appearance, good free liquidity and stable iodine content.

2) Low loss, the loss of NaCl is under 10%.

3) Low energy consumption and investment.

4) Equipment has long service life, easy to operate and maintain.