Starting a soap factory: the first steps and technical choices to consider

Establishing a Soap Factory: Where to Begin

When deciding to start a sabun fabri̇kasi, the initial choices directly impact sustainability, production efficiency, and brand positioning. Clearly defining the business model, analyzing the reference market, and understanding current regulations are fundamental steps. From the type of soap you intend to produce to your business strategy, everything needs to be meticulously planned to avoid waste and maximize profits.

Rising supports businesses in the design and implementation of customized soap production equipment, offering scalable and highly personalized solutions. With deep technical knowledge and industry experience, their goal is to simplify the production process from the outset, ensuring reliability and innovation. Relying on machines tailored to your production needs allows you to start from the right foundation, laying a solid base for business growth.

Choosing the Type of Soap to Produce for Starting a Soap Factory

When deciding to start a sabun fabri̇kasi, determining the type of product to produce from the outset can guide every technical and business decision correctly. You can focus on solid soap, liquid soap, or hand-made soap, depending on your target market and the customer base you want to reach. Each form requires specific factory solutions and offers different profit margins.

For example, traditional solid soaps are suitable for standardized production but can be differentiated through the use of natural ingredients, exclusive fragrances, or personalized shapes. Liquid soaps, on the other hand, are in growing demand in both cosmetic and industrial sectors, requiring high-precision dosing and packaging equipment. Handmade soaps are also rapidly expanding, especially those that emphasize sustainability and skincare.

Evaluating the characteristics of the soap you want to produce from the beginning can help you define the most appropriate saponification line and choose soap-making machines that align with your goals. With Rising’s technical support, you can design a tailor-made factory that perfectly fits your entrepreneurial vision and the quality you wish to offer.

Starting a Soap Factory: Planning the Production Space and Logistics

When you decide to start a sabun fabri̇kasi, efficiently organizing the production space is essential to ensure continuity and safety at every stage of the process. The layout of the facilities should follow a linear logic that facilitates the flow of raw materials and finished products, reducing downtime and unnecessary movements. A careful planning of the environment allows you to improve productivity and optimize the use of resources.

First, you need to decide the raw material you want to use. Then you need to plan dedicated areas for storing ingredients, spaces for saponification, vacuum drying sections (if you want to start from oil), mixing, milling, extruding, cutting, stamping, packaging, and etc. Paths for personnel and safety exits must be integrated from the design phase. Logistics efficiency is built with rational choices that take into account the type of soap produced, the expected production volume, and the possibility of future expansion.

Rising supports you in the design of the plant, adapting the equipment to the characteristics of your production space. The machinery for sabun üreti̇mi̇ is configured in a modular way to offer flexibility and compatibility with even complex production processes. Well-structured logistics allow you to reduce errors, speed up processes, and ensure smooth and competitive production.

Machinery and Plants for Starting a Soap Factory

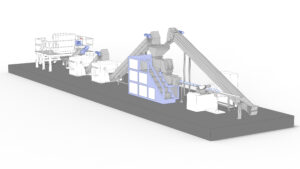

To start a sabun fabri̇kasi efficiently and competitively, it is essential to choose plants designed based on the type of production planned and the scale of the activity. A complete line typically includes

systems for saponification line and finishing line. The finishing line includes mixer, miller, extruder, cutter, stampers, packaging machines, etc. Each machine must be integrated into a coherent production flow, capable of ensuring uniformity, traceability, and flexibility. Soap-making machinery varies in capacity, degree of automation, and compatibility with different raw materials. A modern saponification line should allow precise control of temperature, pH, and reaction time—fundamental parameters for producing a stable and high-performing soap. The choice of modular plants allows for easy scaling of production and adapting to market variations or new formulations.

Rising designs and builds custom soap production plants, with a specific focus on performance, reliability, and ease of maintenance. Each machine is designed to integrate perfectly with the others, optimizing the entire process. Investing in cutting-edge technology from the initial phase allows you to avoid bottlenecks, reduce waste, and achieve a consistent final product, ready to meet even the most demanding markets

Automation, quality control, and sustainability: what to consider when deciding to start a soap factory

When deciding to start a sabun fabri̇kasi, integrating automated solutions allows you to increase efficiency, reduce errors, and improve the overall quality of the product. Automation enables real-time monitoring of every phase of the process, from saponification parameters to the temperature of extrusion, ensuring uniformity and traceability. An automated plant also reduces the need for manual interventions, optimizing staff employment and increasing productivity.

Quality control must be an integral part of the system, not just a final step. Sensors, digital systems, and intuitive interfaces allow for the immediate identification of any anomalies, avoiding waste and rework. The quality of the soap depends not only on the ingredients but also on the precision with which each step is executed.

Sustainability is another key aspect in process optimization. Efficient plants reduce energy consumption, limit waste, and allow for the reuse of process water. Rising integrates technical solutions in its plants designed to minimize environmental impact without compromising production yield. A technological, sustainable, and controlled approach allows you to build a solid factory, ready to face the market with efficiency, responsibility, and quality.

Establishing a Soap Factory: Initial Investment and Costs to Consider

Establishing a sabun fabri̇kasi requires a careful evaluation of the initial investment, which should include not only the purchase of machinery but also the setup of the facility, staff training, and operational costs expected in the first few months. Defining a realistic budget is essential to avoid delays and ensure a solid and well-structured start.

The main costs relate to the production plant: a complete soap-making line equipped with advanced technologies represents the most significant item. Additionally, there are expenses for masonry work, general utilities, raw material procurement, and regulatory compliance. Regular maintenance of the sabun üreti̇mi̇ machinery must also be considered, as it affects operational continuity and the longevity of the plant.

Relying on an experienced partner like Rising allows you to plan your investment more precisely by choosing modular and scalable solutions that fit your business. Optimizing production processes, along with an efficient plant, enables you to recover your initial investment more quickly and manage operational costs over the medium and long term. Prudent resource management is the first step in building a competitive and sustainable factory.

For more information, we invite you to contact us by clicking here.