1000-1200kg/h Toilet Soap making machine & Laundry Soap Finishing production line:

Toilet soap or laundry soap making machinery for soap forming production line

technical data:

Manufacturing standard:.

Meet CE standard and the control system meets C3 requirements.

Mechanical design requirements:.

1. the laundry soap from rotary cutter or the toilet soap from stamping machine enter automatic-feeding device of wrapping machine by conveyer.

2.adopt Japanese Panasonic double servo motor control, high speed and precision, Adopting photoelectric control to make the feeder machine, packaging machine, rotary cutter or stamping machine run together. .

3 by touch screen, simple operation, .

4 450mm wide: the largest membrane.

Packing: 20-240 block/points.

Bag long range: 75-370mm.

Packing width: 20-140m

packing speed: 20-240pcs/min

Below find our product range in mini lab soap machine, 100kg/h, 150kg/h, 300kg/h, 500kg/h, 800kg/h, 1000kg/h, 1500kg/h, 2000kg/h, 2500kg/h, 3000kg/h soap line. Any question pls don’t hesitate to contact us.

Product Overviews

Lab Soap Machine/ Pilot Soap Machine (make soap no more than 100g)

100kg/h or 150kg/h Soap Machine

500kg/h, 1000kg/h, 1500kg/h, 2000kg/h Laundry Soap Finishing Line making from soap noodles

500-1000kg/h Toilet Soap Finishing Line making from soap noodles

1000kg/h, 1500kg/h, 2000kg/h Toilet Soap & Laundry Soap Finishing Line making from soap noodles

Soap Noodles Plant from oil (Saponification Process + Vaccum Drying Process)

Soap Noodles Plant from oil (Saponification Process + Vaccum Drying Process)

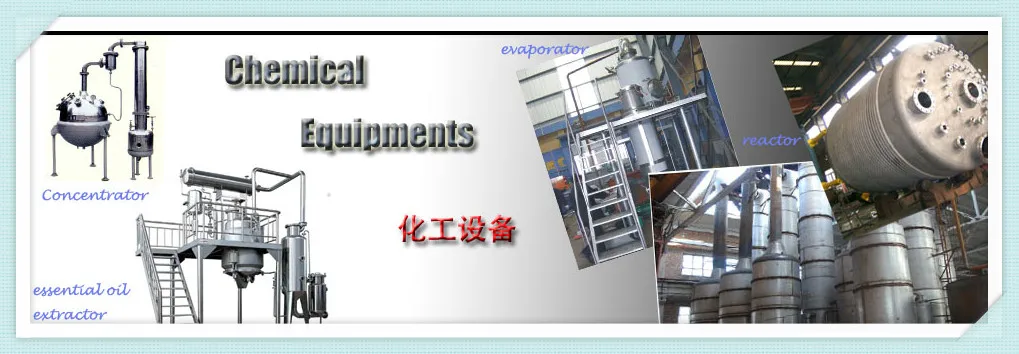

We still make some other Chemical Machines like drum Flakeras/Sewage Treatment Unit etc. below:

Certifications

Factory sites

Trade Shows

With Clients

FAQ